The most expensive phone call Tim Cook ever made might have been to his China manufacturing team. Because while Apple was busy perfecting supply chains in Shenzhen, a quiet revolution was brewing 2,000 miles southwest—one that just turned India into America's iPhone factory and insurance policy against trade volatility.

What you need to know: Apple's Indian operations are projected to hit 60 million units this year, up from 35-40 million in 2024. Meanwhile, iPhone sales in India smashed Q1 records with over 3 million units shipped. Here's the kicker: exports from India reached $12.8 billion last year—a 42% jump that makes India Apple's second-largest iPhone producer globally and the strategic cornerstone of American supply chain security.

What makes India Apple's new manufacturing powerhouse?

Let's talk numbers that'll make any supply chain manager's head spin. India's smartphone manufacturing is expected to capture 20% of global output in 2025, with India recording double-digit percentage growth. But Apple isn't just riding the wave—it's orchestrating the entire transformation through strategic manufacturing depth that goes far beyond simple assembly.

The secret sauce? India's Production-Linked Incentive (PLI) scheme, which covers 14 key sectors and has generated actual investments of ₹1.61 lakh crore ($18.72 billion). For smartphones specifically, all three of Apple's major contract manufacturers—Foxconn, Pegatron, and Wistron (now Tata)—are leveraging this scheme to build capabilities that rival Apple's decade-old China operations.

Here's what really gets interesting: Apple's local value addition has jumped to 15-20% depending on the model, up from 5-8% when the PLI scheme started. That's not just assembly—that's actual manufacturing depth that creates strategic independence and positions India as a legitimate alternative to China's ecosystem dominance.

Think of it as Apple building the manufacturing equivalent of a backup quarterback who's good enough to start. The PLI scheme results demonstrate that India isn't just assembling phones—it's developing the supplier networks, technical expertise, and quality systems that enable true manufacturing autonomy.

How India became America's iPhone insurance policy

Remember when "Made in China" was synonymous with iPhones? Those days are ending faster than you can say "tariff war," and the urgency is driving decisions that would have been unthinkable just three years ago. Apple aims to source most US-bound iPhones from India by the end of 2026, shifting from the current reality where roughly 80% of America's 60+ million annual iPhone sales come from China.

The transformation is happening at breakneck speed. During March-May 2025, Foxconn shipped $3.2 billion worth of iPhones from India, with an average 97% going to the US—compared to just 50.3% in 2024. That's not gradual diversification; that's emergency supply chain surgery performed in real-time.

Why the rush? Having tracked Apple's supply chain evolution since the early China expansion, this acceleration mirrors historical patterns where geopolitical pressure creates manufacturing opportunity. While manufacturing costs in India are 5-8% higher than China, that premium looks microscopic next to potential tariff scenarios. The alternative—manufacturing iPhones in the US would triple costs to $3,000 per unit—makes India look like the bargain of the century.

What's truly remarkable is how Tim Cook announced that all iPhones sold in the US in the June quarter will be shipped from India—a strategic pivot that establishes India not just as Apple's Plan B, but as the primary lifeline for American consumers. This demonstrates manufacturing agility that creates competitive advantages beyond cost savings.

What this surge means for iPhone pricing in America

Here's where things get complicated for your wallet, and where Apple's Indian gambit faces its biggest test. Made-in-India iPhones now face 26% US tariffs, compared to the 100%+ duties China was facing. That's still a significant cost that has to go somewhere—and according to our analysis of similar manufacturing transitions, companies typically split the burden between margins and pricing.

As Counterpoint Research warns, Apple will either have to "pass the cost on through increased prices of iPhones to encapsulate the tariffs or compromise on their margins or both." Translation: your next iPhone might cost more, or Apple's legendary profit margins might finally take a hit. Cool, but not "subsidize tariffs from profit margins indefinitely" cool.

But here's the strategic twist that changes everything: India's domestic iPhone market is exploding. With iPhone sales hitting an estimated $10 billion in India last year and the company achieving an 11% market share, Apple has built a new revenue stream that creates pricing flexibility and risk mitigation impossible with export-only operations.

The scale creates strategic lock-in effects that benefit long-term pricing stability. Apple now employs 185,000 people directly in India, making it India's largest private-sector employer, with over 70% of those jobs held by women. That's not just manufacturing—that's economic infrastructure that enables Apple to absorb short-term cost pressures through operational efficiency and market expansion rather than immediate price increases.

The quality challenge that nobody talks about

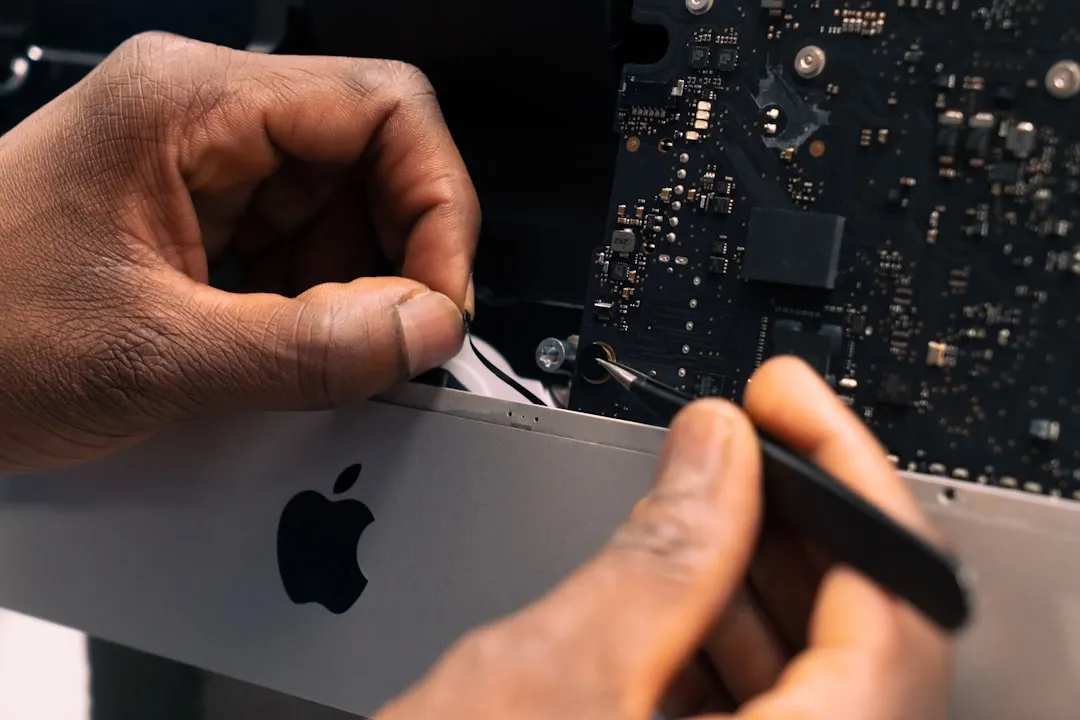

But let's address the elephant in the room that every supply chain expert is watching: quality control. This quality learning curve mirrors a familiar pattern from Apple's early China expansion, but with crucial differences that suggest an accelerated improvement timeline.

About 50% of iPhone housings produced at Tata's Hosur facility are failing Apple's quality standards. That's compared to Apple's goal of zero defects—a gap that explains why Apple has been sending engineers from California and China to Indian facilities, replicating the knowledge transfer playbook that worked in China but with modern manufacturing techniques and compressed timelines.

The historical context matters here. An Indian Foxconn plant was temporarily shut down in 2021 due to health violations in worker accommodations, and subsequent inspections found 77 pieces of automated machinery missing safety mechanisms and 262 instances of missing guards on pressing machinery. These weren't just quality issues—they were fundamental infrastructure gaps.

Based on our analysis of similar manufacturing transitions, these aren't permanent problems, but they represent the current reality that directly impacts consumer confidence and supply chain reliability. Apple's response has been characteristically thorough—increasing audit frequency and investing heavily in local training and infrastructure. The company's commitment signals long-term confidence: if momentum continues, Apple could reach $30 billion in annual Indian production, raising India's share of global iPhone production to over 26%. What these improvement trajectories enable strategically is supply chain independence that protects both quality standards and delivery commitments regardless of geopolitical disruptions.

Where do we go from here?

The implications extend far beyond Apple's balance sheet into reshaping global manufacturing hierarchies. Smartphones have become India's largest export category, with exports reaching $18.31 billion and surpassing automotive diesel fuel. iPhones account for two-thirds of that total—a remarkable transformation for a country that ranked 167th in smartphone exports in 2014.

For American consumers, this shift represents both opportunity and uncertainty with clear timeline implications for upgrade decisions. Industry estimates suggest Apple will maintain 10-15% year-on-year growth in India through 2025, potentially reaching 13-14 million units sold domestically. This growing market creates what economists call "local content subsidization"—where domestic sales help offset higher manufacturing costs for export units, potentially stabilizing American iPhone pricing despite tariff pressures.

The bigger picture? Apple is building redundancy into the world's most valuable supply chain while creating competitive advantages that extend beyond cost management. Reaching production thresholds of 26% global iPhone output enables strategic capabilities like rapid model diversification, regional customization, and supply chain resilience that benefit consumers through better availability and feature localization.

The next evolution phase involves component localization that could fundamentally change supply chain economics. Apple is already prioritizing value addition in India by onboarding Indian and predominantly non-Chinese suppliers for components that account for around 50% of mobile phone costs. This progression from assembly to component manufacturing represents the holy grail of supply chain independence.

Bottom line: India isn't just Apple's Plan B anymore—it's becoming Plan A for American iPhone sales, strategic supply chain resilience, and competitive positioning in an era of trade uncertainty. Whether that means slightly higher prices or improved availability during global disruptions, what's certain is that your next iPhone upgrade is riding on a supply chain revolution that's rewriting the rules of global manufacturing, one Bangalore assembly line at a time. And frankly, that's probably the best insurance policy American consumers could ask for.

Comments

Be the first, drop a comment!